All benefits at a glance

Efficency

Optimal measurement volume/footprint ratio:

- Space-saving design for a small footprint

- Generous and easily accessible measuring volume

- Loading from three sides and from above

- No compressed air required

Speed

Reduced operating times and fast measurements:

- Fast scanning with ZEISS VAST XXT

- Single-point measurements with ZEISS VAST probing

- ZEISS Duplex System for increased throughput

- Four-axis measurement with rotary table

Precision

Precise results even in harsh environments:

- Dust and moisture protection

- IP54 rated ShopFloor base

- Thermal stability due to glass ceramic scales

- Linear drive nut and ball bearing guiding system with covered guiding in all axes

- Passive vibration damping as standard

Fully equipped for your challenges

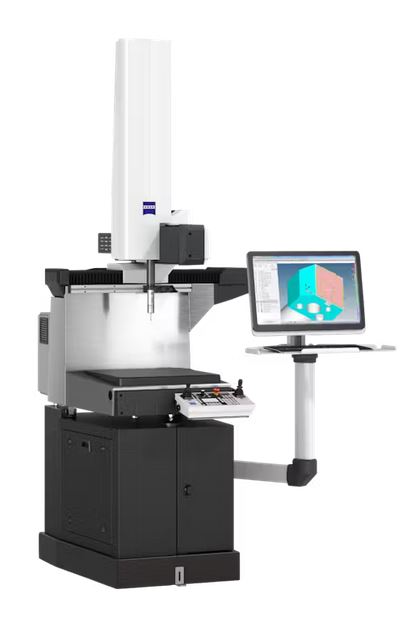

Discover the unique features of ZEISS DuraMax

ZEISS VAST XXT: ZEISS VAST XXT allows single-point measuring and scanning. This offers optimal productivity with stable results. The scanning technology enables the measurement of a massively higher point density and thus a better evaluation of size, shape and position tolerances. A wide spectrum of styli allows you to measure more complex features on more parts!

Measurement Volume: ZEISS DuraMax offers an unbeatable measuring volume/footprint ratio. Optimal accessibility, a clear view into the measuring volume as well as loading at an optimal working height from three sides and from above improve ergonomics and safety and reduce operating times.

Rotary Table: In combination with the optional rotary table, you gain even greater flexibility for rotational symmetrical small parts, allowing you to measure complex tasks with a fourth axis. This not only reduces the complexity of stylus systems, but also the operating time due to fewer probe changes.

Temperature Resistivity: All axes are equipped with glass-ceramic scales. These do not expand with increasing temperature, allowing stable measurements at temperatures from +18 °C to +30 °C. The IP54 base protects the computer hardware.

Pneumatic Vibration Isolation: The optional pneumatic vibration isolation prevents the influence of ground vibrations on measurement results and provides automatic level control. It can also be retrofitted for ZEISS DuraMax and ZEISS O-INSPECT.

ZEISS CALYPSO: The intuitive software ZEISS CALYPSO offers a high level of flexibility for different measurement tasks, while ZEISS CALYPSO express enables simple programming. The single-point mode for ZEISS DuraMax now also allows you to operate your tactile sensor in ZEISS VAST probing mode, saving you up to 25-80% measurement time depending on the task.

Accessories: ZEISS Integration Series enables the flexible expansion of your measurement solution for optimal integration into your existing processes and an increase in productivity and throughput.

Even less temperature-sensitive, even more robust

ZEISS DuraMax HTG

ZEISS DuraMax HTG offers the widest temperature range with the highest temperature gradient and can be operated both at the production site and in automation systems. This provides more flexibility as you can perform your measurement tasks with even more resistance to environmental influences.

Highlights:

- Precise measurement at high temperatures

- Zerodur scales for smallest possible heat expansion

- Thermal stability due to glass ceramic scales

- Temperature sensors for workpiece temperature correction

- Additional filter pads in the X- and Y-axis to protect against dirt and dust

Matching solutions for every measurement task

ZEISS Integration Series

The product range of ZEISS Integration Series allows for flexible expansion of your measurement solution to ensure optimal integration into your existing processes and for an increase in productivity and throughput. Duplex System: The duplex system for ZEISS DuraMax improves machine utilization, as the workpieces can be clamped and unclamped in parallel to the measuring process. In addition, the system improves the ergonomics of part handling and prevents damage to the measuring systems.

Setup during the measurement process:

- Optimized CMM utilization

- High throughput of workpieces

GageStation: With ZEISS PiWeb, the GageStation combines measurement data from handheld measuring devices with CMM measurement data and visualizes them in a comprehensible manner via tough screens and measurement report templates. The GageStation requires little space and offers protection from environmental influences in the production environment that can falsify measurement results.

Consolidation of all quality data in one report:

- Data acquisition independent of measuring equipment

- Centralized data handling

- Protection against environmental influences

Automation Interface: The ZEISS Automation Interface allows you to easily automate your measuring device without any engineering effort. In addition to starting inspection plans and providing feedback on measurement results or machine status, the application allows you to control CMM peripherals. The interface is also preconfigured for all products int eh ZEISS Integration Series. For example, the control of automatic fixtures of the pallet feed can be configured effortlessly with just a few clicks. Individual fixtures developed by you can also be controlled via configuration.

Easy automation of the CMM periphery:

- Standard communication interfaces: OPC UA, Profinet, EthernetIP

- User administration allows plant operators, measuring technicians, setters or service to see exactly what they need

- Can be used in both automatic and manual mode even by untrained operators

- Simple configuration by click and directly via the user interface, without complex PLC programming.

- Efficient commissioning wiht low project risks and low costs.

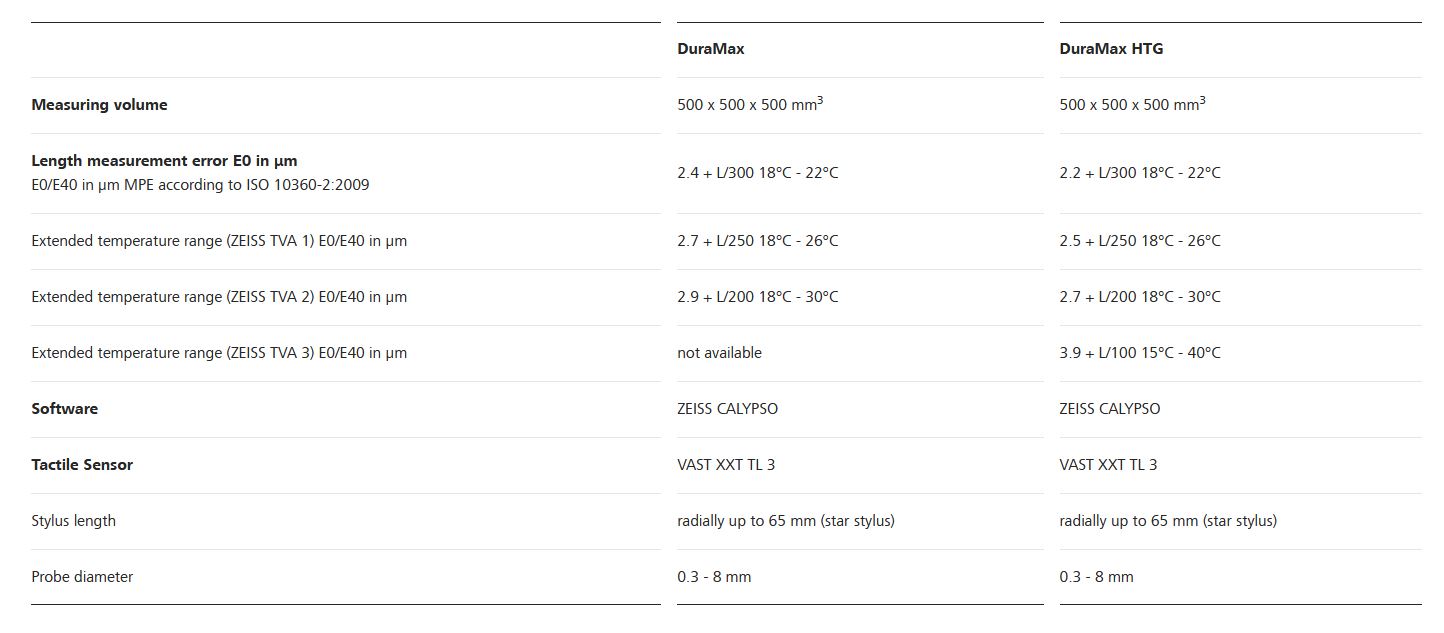

Technical Specifications

|